Aerial Inspection Cameras

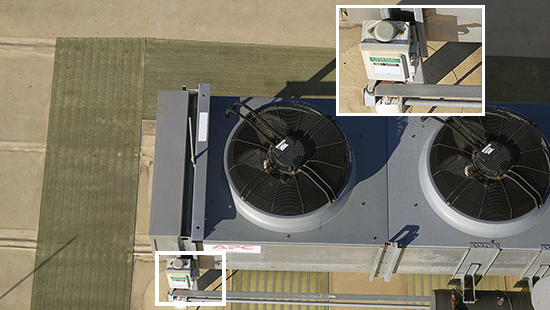

Phase One drone cameras provide invaluable aerial imagery data that enables predictive maintenance for drone inspection missions of powerlines, wind turbines, roads, bridges, and pipelines, as well as agriculture. Our inspection and camera solutions increase the speed and precision of data collection and reduce the costs and risky operations of ground teams.

Our specifically designed drone aerial inspection cameras enable large surface coverage at extremely high resolution. They provide accurate visualization of the objects, as well as the surrounding areas. Phase One UAV cameras also enable millimeter-sized damage spotting detection and fast repair, with minimal effect to performance or the environment – making them the ultimate aerial inspection cameras.

Phase One’s iXM 100MP and iXM 50MP cameras are uniquely designed for drone imaging applications and can be easily integrated with many models of drones to achieve the best solution in UAV aerial inspections.

Read aerial drone inspection camera case studies

NV5 - Capturing precise details, with four Phase One cameras integrated to helicopter-based CLASS platform

NV5 Geospatial is able to provide high-quality data of medium to large scale oil, gas, and electric utility infrastructure in 50% less time by integrating four Phase One inspection cameras into their CLASS helicopter-based platform. Read about how high-value assets require constant high-resolution imagery and data to inspect any health and maintenance concerns and how Phase One inspection cameras have enabled them to collect the required nadir and nadir 4-band, oblique, and high-density LiDAR data in a single pass.

SkySkopes - New Imaging Technology Makes Power Line Inspections Quicker and Easier

SkySkopes uses a helicopter platform with a 100-megapixel (MP) camera to produce high-resolution RGB photographs for quick project turnarounds. Read about the data capture of 174 miles of transmission lines and how Phase One drone powerline inspections provide fine-detail images for inspection analysis.

Siemens and GGS: Revolutionizing powerline inspection with multi-sensor systems

The Sieaero System, implemented by Siemens AG, is a multi-sensor system that records and analyzes all required data in one go using multiple sensors – including five Phase One 100MP RGB sensors – innovative AI, and machine learning. Designed and built by GGS, the combined multi-sensor system along with novel analysis methods, integrates of all observations to create Digital Twins of infrastructure. The helicopter mounted system also optimizes inspection workflow, and also significantly saves time and money.

Eyefly – Achieve close-to-1 mm GSD with a large footprint for 3D bridge inspection

Eyefly uses a Phase One iXM-100 to fly closer to Buggenum Railbridge and achieve a resolution of nearly 1mm with an image footprint of 12m x 9m from a flight height of 10 meters distance. Data is used to create and provide a 3D mesh and inspection platform of the structure for the required annual bridge inspection.

AM/NS Calvert (ArcelorMittal) - Property inspection – Acquiring data in 70% less time

AM/NS Calvert Steel Mill uses a Phase One iXM 100MP medium format imagery to meet new regulatory commercial grade requirements on data collected for asset inspection. Additional benefits were realized when the project was completed with a 70% time saving.

Airbus - Using high-resolution RGB cameras to create high-definition 3D thermal models

Airbus Defence and Space acquired Phase One iXM-100 cameras to be integrated as a payload in the ALTAIR airship. The airship’s large payload capacity allows for more than one sensor system for 3D mapping and was used recently for a pilot project between Airbus, vaireco and MVV Energie AG to generate high-definition thermal 3D models using a combination of infrared (IR) and RGB data captured simultaneously.

AeroInspekt - A closer aerial inspection of automated shipping yards in motion

Storage cranes at Hamburger Hafen und Logistik AG’s (HHLA) modern and efficient shipment yard require an annual survey of over 30km of rail per terminal. A research team at TU Braunschweig – AEROINSPEKT has developed a system to perform airborne measurement of critical infrastructure in operation, thus reducing downtime required by manned ground inspection.

Phase One Industrial’s 100MP imaging technology completes the Phoenix Vision360 solution as it meets all our requirements, plus its compact size and weight allow for easy integration with our UAV-based platforms.

Phase One’s iXM-100 is the only camera that can capture such sharp and large images with its wide swath, from a safe altitude. The camera just works with no triggering problems.

Our business has grown since we started with Phase One cameras, as we are able to provide our customers with all the data that they need in one flight. The result is satisfied end-users who come back, as we can provide them with more details and better accuracy than we could with lower resolution sensors.

With our Phase One System we have increased coverage by over 60% in the same amount of flight time as we did with previous sensors, increased the quality of data by 400%, and the camera has already paid for itself at least twice this year for all our inspection and mapping missions.

Keep informed about

Phase One Geospatial

We send regular newsletters with case studies, white papers, videos, event and webinar invitations, and other great information on drone inspections and more. Sign up to keep informed!