Unlocking Efficiency: The Holistic Approach to Drone-Based Utility Inspections

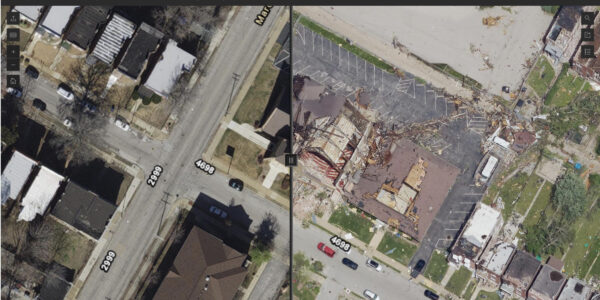

In an era where technology reshapes industries at an unprecedented pace, drone-based utility inspections have emerged as a transformative force. Picture this: A decade ago, utility companies grappled with the limitations of traditional inspection methods, facing challenges in scalability, efficiency, and regulatory compliance. Fast forward to today, and these challenges have been met head-on, thanks to the integration of drone technology into utility inspection processes.

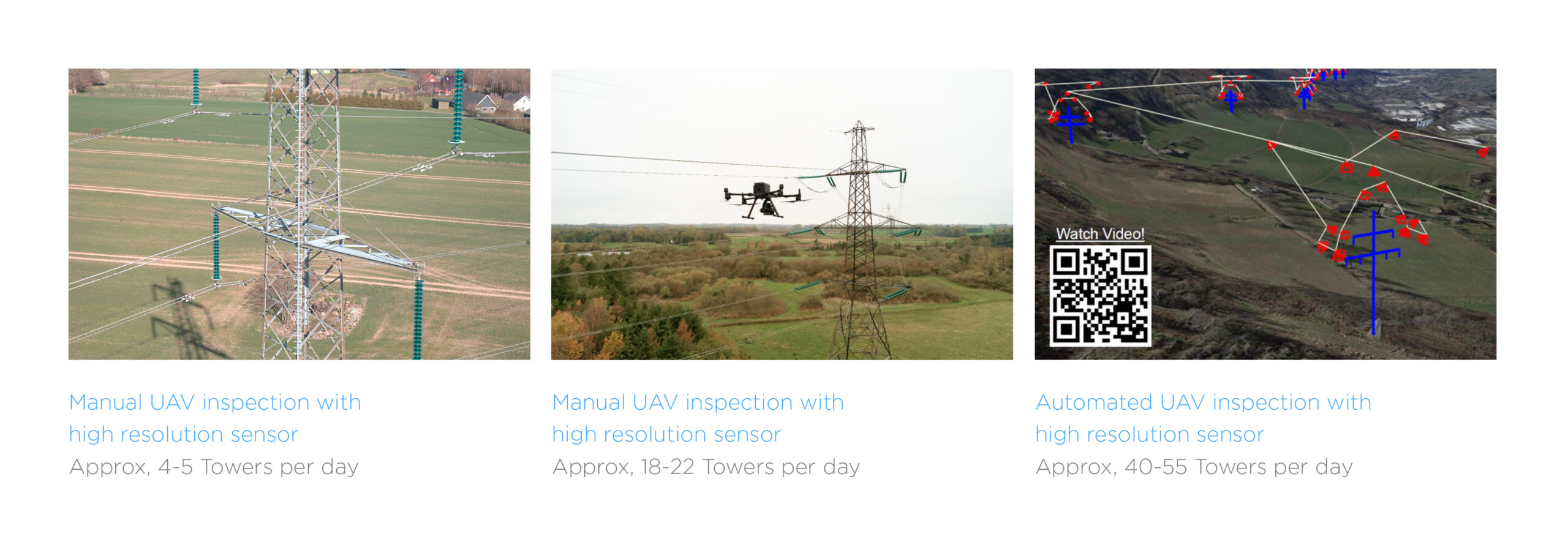

Large utility companies have managed a tenfold increase in productivity with their drone-based inspections by using high-quality cameras combined with automated flights, purpose-built inspection software and efficient data analytics.

Productivity in an inspections context

Inpections Productivity

=

The value of image capture, conversion, and analysis

÷

Man-hours required to create that value

Conventional inspection solutions such as small drones have proven viable. However, they have also shown how difficult it is to scale these solutions to the complete grid. But with the right cameras, automated flights, and Artificial Intelligence (AI) based analytics and software, scalable and efficient asset inspections are possible.

How? By using a holistic approach and optimizing every step in that process to increase productivity. This holistic approach not only elevates the value of collected data but also significantly reduces the time required for both capture and analysis. Moreover, scalability is a key aspect of this approach. If inspections lack scalability, they become vulnerable to future challenges, potentially resulting in increased costs and decreased efficiency. It is essential to prioritize scalability early on when embracing holistic, drone-based inspection programs. A crucial optimization step involves leveraging advanced image capture technology and employing superior cameras. This deliberate choice yields a substantial return on investment in inspection program. The high-resolution images produced provide the right teams with precise visual data, empowering them to make informed and actionable decisions.

Besides finding defects, the images can train an AI model to help detect defects in inspection software. Over time, this can bring many benefits because you are also creating a highly valuable image-based data set.

That is just one example. But the point is that if data is the new oil — the new most-valued resource — then you need to think about it in the bigger picture of your asset inspections.

The illustration below shows how one company successfully scaled up, introduced automation, and deployed high-quality cameras. The result of this holistic approach? A tenfold productivity improvement.

In unlocking efficiency through a holistic approach to drone-based utility inspections, we witness not just a technological advancement, but a paradigm shifts in how we perceive, manage, and optimize utility assets. As companies continue to embrace the transformative power of drones, the sky is not the limit—it’s just the beginning of a new era in utility inspections.

Share this on social media: