Asset Inspection of AM/NS Calvert Steel Mill Using High-Resolution UAV Imagery.

Regularly inspected structures ensure smooth consistent working of this mill. Serving the North American market since 2010 and purchased by ArcelorMittal and Nippon Steel Corporation in 2014, the 2,373-acre Carbon Steel Mill in Calvert, AL has the capacity to produce 5.3 million tons of flat rolled carbon steel products annually. To determine the condition of all assets including roofs, drains and AC units, requires constant data and image collection.

In 2019 an upgrade to the grade of the data collected on these assets was implemented. To ensure this increased regulatory Commercial Grade data requirement was met, the mill needed to invest in a higher resolution image capture solution. The Phase One Industrial iXM-100 was chosen to meet their exact needs; a medium format aerial camera with a 1.1 kg payload, compatible with their existing DJI M600 Pro UAV and robust enough for this type of industrial project, whilst at the same time providing consistent and reliable high-resolution data.

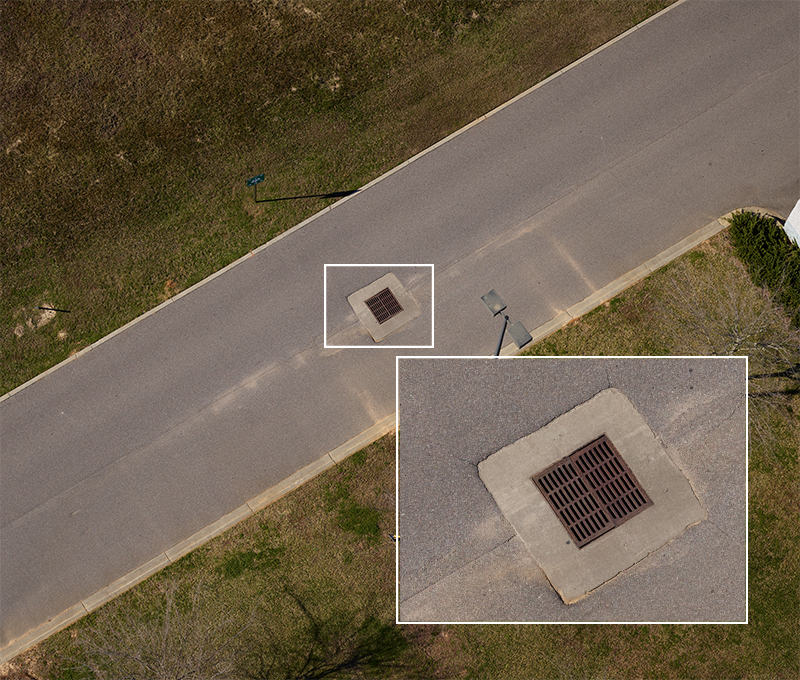

Image: Inspection of drainage taken with iXM 100MP camera and 80mm RSM lens. AM/NS Calvert 2020 ©

With our Phase One system we have increased coverage by over 60% in the same amount of flight time as we did with previous sensors, increased the quality of data by 400% and the camera has already paid for itself at least twice this year for all our inspection and mapping missions. The results and the performance of Phase One Industrial products have more-than met our expectations

Get more details with Phase One

Steel Mill Asset Inspection

AM/NS Calvert is a 50/50 joint venture between ArcelorMittal and Nippon Steel Corp. (NSC). A Carbon Steel Mill in Calvert, AL.

Recognized as one of the most advanced steel finishing facilities in the world, the facility includes a river terminal, hot strip mill, cold rolling mill, three hot dip galvanizing lines, rail yard and supporting infrastructure. With the capacity to produce 5.3 million tons of flat rolled carbon steel products annually, serving the North American market since 2010, mapping and inspection of the assets are of upmost importance.

The facility serves the automotive, construction, pipe and tube, service center, and appliance/ HVAC industries with an impressive portfolio of steel grades for high-value applications including hot rolled bands, hot rolled pickled and oiled, cold rolled, and advanced coated products and employs over 1,500 people.

Image: AM/NS Calvert is recognized as one of the most advanced steel finishing facilities in the world and is highly complementary to ArcelorMittal’s existing portfolio of world-class assets . AMNS Calvert 2020 ©

Commercial Grade Data Requirements Increased

Mapping the existing site of the Steel Mill along with some new project areas is an ongoing project in Calvert. Asset inspection to record the physical level and condition of structures, roofs, and utility assets is necessary to keep the mill running safely and efficiently. In 2019, requirements to collect Commercial Grade hardware and regulatory grade data were increased, meaning that a higher resolution data collection solution was needed.

UAV technology was already in use to collect this data prior to the required increase grade data. The obvious upgrade in technology called for medium-format imagery. Initial challenges were to find a medium-format camera with a low enough payload for integration with an existing DJI M600 Pro and existing in-house software, but the camera needed to be robust enough for Industrial work. AM/NS were looking for predictable and consistent delivery of high-resolution quality data.

Key features that drew them to the Phase One Industrial cameras were the simplicity and flexibility in set-up and the in-flight control. In addition to the ease of post-processing of the data. With excellent post-sales support, the data collection team was able to upgrade the project to the increased grade data needed very quickly and smoothly. Using the system at a minimum of 3 – 4 days a week since it was acquired.

IMAGE: Inspection of the property’s roof taken with iXM 100MP camera and 80mm RSM lens. AM/NS Calvert 2020 ©

Increased Coverage and Safety Margins

By utilizing the iXM 100 Camera with the 35mm RSM lens AM/NS Calvert have been able to cover more area in less time with much better resolution for mapping. Similarly, having the ability to use the same camera with the 80mm RSM lens they have been able to take images from a greater distance than previously, increasing the safety margin and at the same time also increasing area coverage by over 60%.

“Both configurations yield clear actionable data both from the clarity of the images and their ability to process and provide much more accurate point cloud data.” commented Mathews. “The results and the performance of Phase One Industrial products have more-than met our expectations!!!”

The upgrade in data collection solution has enabled a larger area (63% increase) to be covered per flight with the iXM 100, providing greater resolution for mapping all detail in the same amount of time. Structural inspections have been conducted in less than a quarter of the time it took using their previous traditional methods.

The increased level of detail from the 100MP camera allows an engineer or maintenance technician to now be able to quickly and easily evaluate the condition of a particular structure or asset with the same, and in most cases better, level of confidence as with traditional visual inspections in much less time and in a much safer environment.

IMAGE: A Phase One iXM 100MP Camera and interchangeable 35mm RSM and 80mm RSM lenses were purchased as the camera delivers the high quality needed for the asset inspection and also easily integrates with the DJI M600 Pro drone. AM/NS Calvert 2020 ©

Geospatial

Monitoring pipeline corridor using PAS 280 large format camera

Geospatial

Preventing Wild Bushfires By Mapping Planned Burns

Geospatial

Novice Aerial Photographer Becomes Advanced Mapping Provider

Geospatial

Inspecting Wind Turbine Blades While They Are Rotating

Geospatial

Precision at Altitude: Redefining Aerial Mapping with the PAS 880 Oblique Camera System

Geospatial

Perfecting telescope dish accuracy with UAV photogrammetry

Geospatial

Saving costs while lowering carbon footprint: Innovative aerial surveying service uses small airplanes enabled by compact cameras

Geospatial

Detecting forest tree diseases using a large-format camera on an ultralight aircraft

Geospatial

Mapping lava flows during volcanic eruptions in Iceland

Geospatial

The PAS Pana: a 48,800-pixel camera innovated with our customer Surdex

Geospatial

Rebuilding after Hawaii’s wildfire with engineering-grade surveying

Geospatial

Revolutionizing Slovenian urban planning: Phase One’s PAS 880i redefines reality mapping

Geospatial

Imaging solutions combined with AI and 5G – A new approach and promising to assess forest health and detect and monitor wildfires

Geospatial

Phase One Cameras combined with light, fixed-wing aircraft deliver highly efficient LiDAR and mapping missions

Geospatial

Capturing Glastonbury Festival

Press Release

Phase One strengthens distribution network with DroneStars for Enhanced UAV Inspection in the Benelux region

Geospatial Blog

Unlocking Efficiency: The Holistic Approach to Drone-Based Utility Inspections

Press Release

Phase One expands distributor reach with Measur for strong UAV inspection growth in the Canadian market

Geospatial Blog

Technology Turning the Tide Against Ocean Plastic Pollution

Geospatial Blog

Setting the New Standard: Evaluating Survey-Grade Accuracy with the Phase One P5

Press Release

Phase One Partners with gNext to Revolutionize Asset Inspections based on Intelligent Image Quality (IIQ)

Geospatial Blog

Part One of: Taking Off – a checklist for the start of the inspection flying season

Geospatial Blog

Insights and future trends at Geo Week 2024

Press Release

Cyberhawk selects Phase One in their pursuit of revolutionizing drone-based industrial inspection by delivering more value in less time.

Press Release

SPH Engineering and Phase One Team Up to Enhance Visual Inspections with ImageInspector Solution

Press Release

Phase One certifies Xer Technologies’ hybrid electric X8 BVLOS capable UAS for next-generation high-resolution inspections

Press Release

Phase One and Boston Announce Partnership for strong Drone Imaging collaboration in the Nordics

Geospatial

Phase One Selects Globe Flight as Sales Partner for Drone Solutions in Germany and Austria

Press Release

Phase One ernennt Globe Flight GmbH als Vertriebspartner für Drohnenlösungen in Deutschland und Österreich

Press Release

Remote Vision Named as Swiss Reseller of Phase One Drone Payloads