Airbus ALTAIR – A First for Large Scale High Definition 3D Mapping Solutions

Airbus Defense and Space acquired Phase One Industrial iXM-100 aerial inspection cameras with 35mm lenses to be integrated as a payload in the ALTAIR airship.

ALTAIR offers the first autonomous unmanned airship (Zeppelin), which is allowed to fly in cities and over crowds. Thus it enables the collection of high-resolution and ultra-precise optical data, which are processed into 3D city models of unmatched quality. The digital products of ALTAIR are the foundation to assist in smart decision-making and realistic simulations to pave the way for future cities.

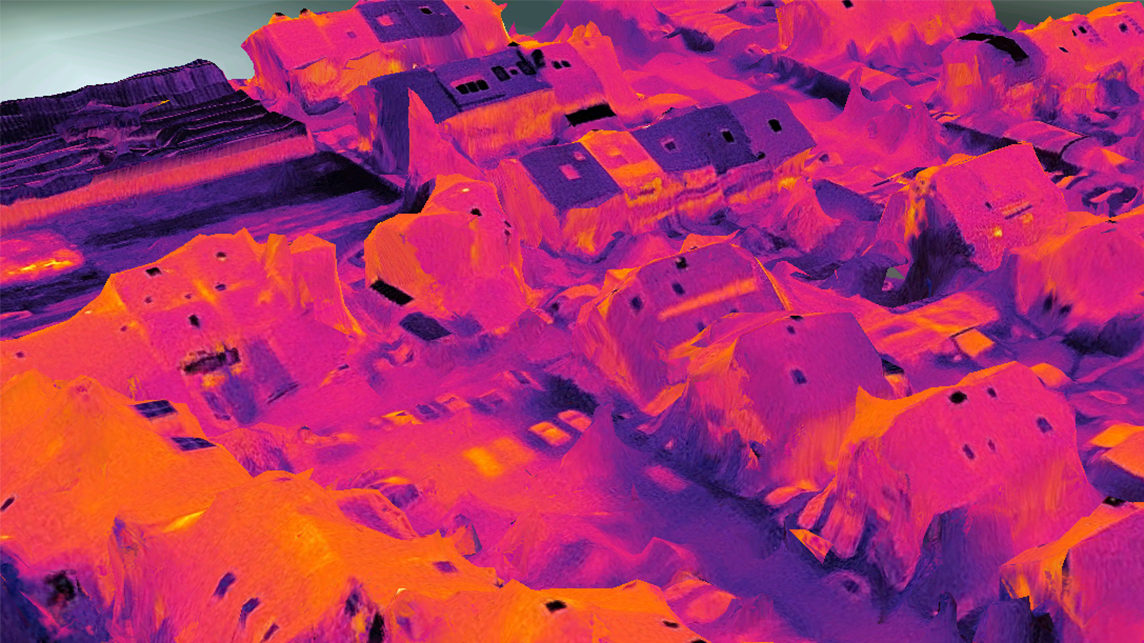

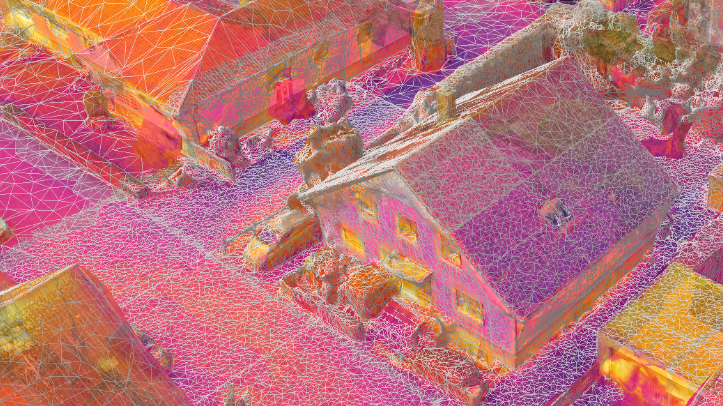

image: Airbus and vaireco USES high-definition thermal 3D CITY modelING using a combination of infrared and high-resolution RGB data, from Phase One Industrial 100MP cameras, captured simultaneously aboard the airship – Airbus 2020 ©.

Phase One 100MP cameras are an integral part of our IR 3D mapping solution as they provide us the baseline for a high definition 3D meshed model to be fused with IR data captured in one flight

Capture an Entire City in One Flight

Altair combines robust and proven airship platforms with latest technology to enable UAV remote sensing over cities, crowds, and beyond visual line of sight (BVLOS) missions for the first time.

The ALTAIR has a flight endurance of 3 to 8 hours, maximum payload of 10kg, flies at 60km/h, and reach a maximum height of 1800m. The airship is therefore ideal for aerial 3D Mapping on a city scale at low altitudes for data acquisition at a high GSD.

Airbus, vaireco (a 3D inspection technology startup) and MVV Energie AG (one of Germany’s leading energy companies) embarked on a project to acquire high-definition 3D IR data on a city scale using thermal sensors and Phase One Industrial 100MP RGB cameras, showcasing the potential of integrated 3D mapping solutions.

- The benefits of the airship are:

- 10 times longer flight time compared to multicopters.

- Low noise and high public acceptance allow for special missions even at night

- Designed for safety, ALTAIR can fly where other aircraft and UAVs cannot

- Real-time and high-quality data service available remotely wherever you are

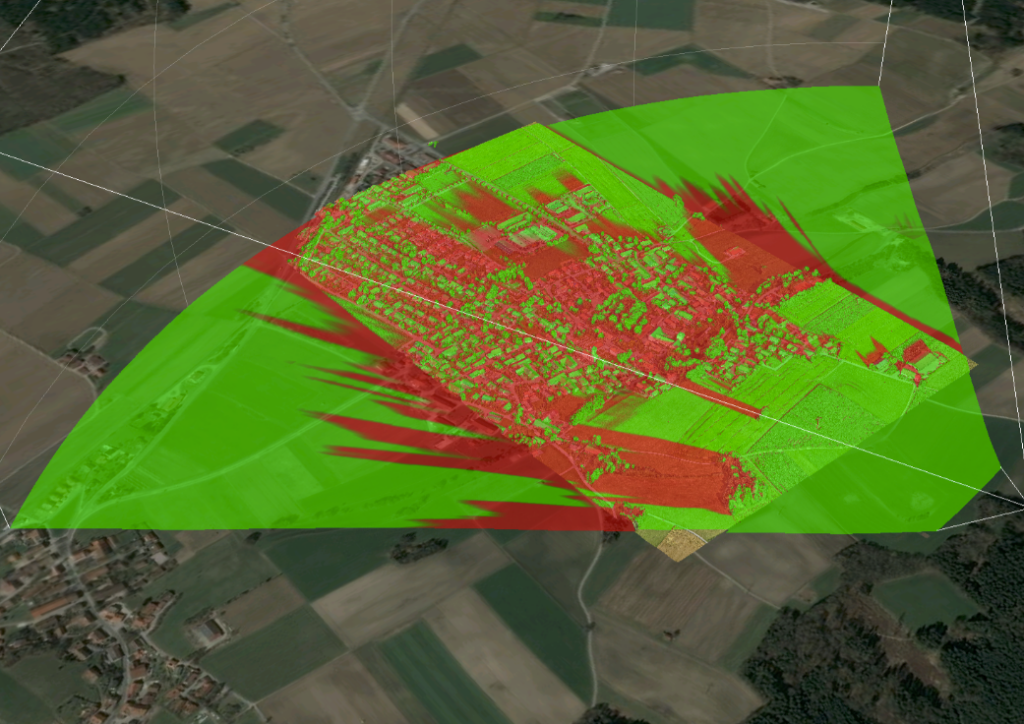

image: Designed to fly sensors over critical infrastructure and cover city scale areas, ALTAIR is ideal for Antennae Signal Propagation projects – Airbus 2020 ©.

Get more details with Phase One

Energy Saving through Large Area Thermographic Data

Clemens Peters – consultant at MVV Energie AG – explains: “Large-area thermographic data acquisition of complete city infrastructures allows municipalities to support citizens to achieve energy saving targets, e.g. via our new platform CLIMAP. The data provides a decision baseline for renovation activities as well as support and allow prognoses on cost-saving effects.“

image: Low-resolution thermal model captured with just IR sensors at an altitude of 150m shows a generalized heat map and specific objects are difficult to identify – Airbus 2020 ©.

Creating a Future Industry with Thermal Sensors and High-resolution RGB cameras

“Currently aerial thermal imagery is used by ‘energy optimizers’ to detect sources of heat loss in buildings and homes. Our new high-definition imagery opens up new uses and opportunities for people to implement this technology in such as Firefighters; Police; Administrations for monitoring; Architects; Maintenance crews; Safety bodies; and Environmentalists. We are only in the middle of exploiting all the new use cases with domain partners,” – Robert Holder: Innovation Manager, Airbus Defence, and Space.

image: Airbus and vaireco generated high-definition thermal 3D models using a combination of infrared and high-resolution RGB data, from Phase One Industrial 100MP cameras, captured simultaneously aboard the airship – Airbus 2020 ©.

Airbus Defense and Space GmbH. - ALTAIR

The system includes:

- Two Phase One iXM 100 MP Cameras

Mounted diagonal (left-front – right-back)

– Enlarged in the image above - Three FLIR TAU 2 thermal sensors

Mounted Nadir, Diagonal (right-front – left-back)

image: Designed to be flown close to the ground, together with Phase One iXM-100 cameras, you can capture a GSD of 1.5cm when flown at a height of just 150m – Airbus 2020 ©

Redefining Thermal Imaging

The challenge was to develop a system for large-scale scanning, improving the infrared data quality, and process the data into 3D infrared (IR) models. The result has extraordinary analytical potential.

Wolfgang Herbst, business developer at vaireco and IR specialist says: “The combination of both Electro-Optical (EO) and IR 3D Models allow a completely new field of applications for infrared data. At the same time, accuracy and aerial performance are pushed into a new dimension. Thus, a number of new use cases have opened up. E.g. inspection flights of large-scale solar plants. (defect cells in solar arrays usually become hotter than normal).”

The fusion of high-resolution EO data with the low altitude IR data enables the detection of much smaller anomalies over a large scale while providing a direct cross-check with the optical data. This, in turn, leads to faster analysis. Since IR and EO data are captured simultaneously and the optical 3D mesh is used as a reference for IR, both models match naturally. Uses for IR data are increased as it is now represented at the correct geolocation.

image: High-resolution EO data from Phase One iXM-100 cameras (left) is fused with the low altitude IR data (right), which enables the detection of much smaller anomalies over a large scale while providing a direct cross-check with the optical data. – Airbus 2020 ©.

Geospatial

Monitoring pipeline corridor using PAS 280 large format camera

Geospatial

Preventing Wild Bushfires By Mapping Planned Burns

Geospatial

Novice Aerial Photographer Becomes Advanced Mapping Provider

Geospatial

Inspecting Wind Turbine Blades While They Are Rotating

Geospatial

Precision at Altitude: Redefining Aerial Mapping with the PAS 880 Oblique Camera System

Geospatial

Perfecting telescope dish accuracy with UAV photogrammetry

Geospatial

Saving costs while lowering carbon footprint: Innovative aerial surveying service uses small airplanes enabled by compact cameras

Geospatial

Detecting forest tree diseases using a large-format camera on an ultralight aircraft

Geospatial

Mapping lava flows during volcanic eruptions in Iceland

Geospatial

The PAS Pana: a 48,800-pixel camera innovated with our customer Surdex

Geospatial

Rebuilding after Hawaii’s wildfire with engineering-grade surveying

Geospatial

Revolutionizing Slovenian urban planning: Phase One’s PAS 880i redefines reality mapping

Geospatial

Imaging solutions combined with AI and 5G – A new approach and promising to assess forest health and detect and monitor wildfires

Geospatial

Phase One Cameras combined with light, fixed-wing aircraft deliver highly efficient LiDAR and mapping missions

Geospatial

Capturing Glastonbury Festival

Press Release

Phase One strengthens distribution network with DroneStars for Enhanced UAV Inspection in the Benelux region

Geospatial Blog

Unlocking Efficiency: The Holistic Approach to Drone-Based Utility Inspections

Press Release

Phase One expands distributor reach with Measur for strong UAV inspection growth in the Canadian market

Geospatial Blog

Technology Turning the Tide Against Ocean Plastic Pollution

Geospatial Blog

Setting the New Standard: Evaluating Survey-Grade Accuracy with the Phase One P5

Press Release

Phase One Partners with gNext to Revolutionize Asset Inspections based on Intelligent Image Quality (IIQ)

Geospatial Blog

Part One of: Taking Off – a checklist for the start of the inspection flying season

Geospatial Blog

Insights and future trends at Geo Week 2024

Press Release

Cyberhawk selects Phase One in their pursuit of revolutionizing drone-based industrial inspection by delivering more value in less time.

Press Release

Phase One, Quantum Systems and Trimble unveil groundbreaking survey grade UAV solution with the launch of Phase One P5 camera

Press Release

SPH Engineering and Phase One Team Up to Enhance Visual Inspections with ImageInspector Solution

Press Release

Phase One certifies Xer Technologies’ hybrid electric X8 BVLOS capable UAS for next-generation high-resolution inspections

Press Release

Phase One and Boston Announce Partnership for strong Drone Imaging collaboration in the Nordics

Geospatial

Phase One Selects Globe Flight as Sales Partner for Drone Solutions in Germany and Austria

Press Release

Phase One ernennt Globe Flight GmbH als Vertriebspartner für Drohnenlösungen in Deutschland und Österreich